PVC is widely used in many fields, but the odor it produces is troublesome. PVC Odor Eliminator is the ideal solution to this problem.

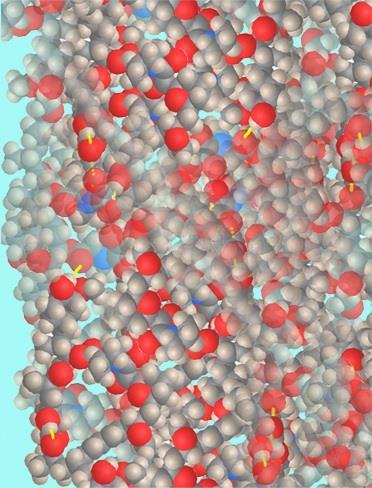

This product adopts advanced composite technology, integrating chemical conversion, physical adsorption and odor shielding mechanisms. The active ingredients it contains can react chemically with the residual vinyl chloride monomer and odor substances in PVC, converting them into low-volatility or odorless compounds; the special porous structure inside is like activated carbon, which strongly adsorbs odor molecules; the added odor shielding ingredients release a pleasant scent to cover up the original odor.

Compared with traditional methods, it has significant advantages. The effect is long-lasting and runs through the entire life cycle of PVC products; the addition method is flexible and can be incorporated into various stages of production without affecting the physical and processing properties of PVC; the material is environmentally friendly, does not contain harmful heavy metals and volatile pollutants, and meets environmental standards.

In terms of use, the operation is extremely simple. During the PVC resin synthesis stage, PVC Odor Eliminator can be evenly mixed into the raw materials in a certain proportion. As the synthesis reaction proceeds, the product can fully play its role and inhibit the generation of odor from the source. When entering the mixing stage, whether it is stirred together with other additives such as plasticizers and stabilizers, or added alone, it can be well mixed with the PVC raw materials to ensure that the odor elimination effect continues to be exerted in subsequent processing. In the PVC processing and molding stage, such as before the extrusion and injection molding process, an appropriate amount of the product can also be added to the material. After high-temperature processing, it can also effectively eliminate odor. Through this flexible and easy-to-operate use method, whether it is PVC pipes, doors and windows for construction, or food and drug packaging, electronic equipment housings and medical PVC products, PVC Odor Eliminator can show its prowess, effectively eliminate odors and improve product quality.